Heat pumps are a highly efficient technology used for heating and cooling homes and buildings. At the core of a heat pump’s operation is refrigerant, a crucial fluid that enables heat transfer between indoor and outdoor environments. Understanding the role of refrigerant in a heat pump helps clarify why these systems are considered energy-efficient alternatives to traditional HVAC systems.

| Feature | Details |

|---|---|

| Refrigerant Function | Transfers heat by cycling through evaporation and condensation |

| Heat Pump Operation | Heats or cools by reversing refrigerant flow |

| Common Refrigerants | R-410A, R-32, R-134a, newer low-GWP options |

| Energy Efficiency | Uses refrigerant phase changes to reduce energy consumption |

What Is Refrigerant and Its Role in Heat Pumps?

Refrigerant is a special chemical fluid designed to absorb and release heat efficiently. In heat pumps, refrigerants continually circulate through a closed loop of coils, moving heat from one place to another by changing from liquid to gas and back. This phase change process is fundamental, enabling heat pumps to extract heat from cold outdoor air in winter or remove heat from indoor air in summer.

The unique thermodynamic properties of refrigerants, including low boiling points and high heat absorption capacity, make them integral to the operation of most HVAC systems, particularly heat pumps.

How Does a Heat Pump Use Refrigerant to Transfer Heat?

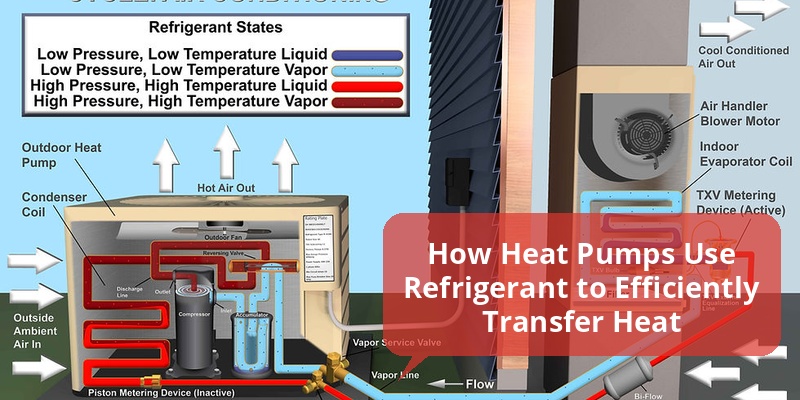

Heat pumps operate on the principle of heat transfer rather than generating heat by burning fuel. The refrigerant absorbs heat at the evaporator coil and releases it at the condenser coil through a cycle driven by a compressor and expansion valve.

- Evaporation: Refrigerant absorbs heat and evaporates from liquid to gas at low pressure.

- Compression: The compressor increases refrigerant pressure and temperature.

- Condensation: Refrigerant releases heat and condenses from gas back to liquid.

- Expansion: The expansion valve reduces refrigerant pressure, cooling it to repeat the cycle.

This continuous cycle enables the heat pump to move heat indoors for heating or outdoors to provide cooling efficiently.

Heat Pump Modes: Heating and Cooling

Refrigerant flow is reversed using a reversing valve, allowing the heat pump to switch between heating and cooling modes.In heating mode, refrigerant extracts heat from the outside air and releases it indoors. In cooling mode, the process is reversed, absorbing heat from indoor air and rejecting it outdoors.

Common Types of Refrigerants Used in Heat Pumps

The choice of refrigerant impacts the heat pump’s efficiency, environmental footprint, and regulatory compliance. Modern heat pumps generally use environmentally safer refrigerants with low global warming potential (GWP).

| Refrigerant Type | Use Case | Environmental Impact |

|---|---|---|

| R-410A | Common in residential heat pumps | Zero ozone depletion but moderate GWP |

| R-32 | Increasingly popular for improved efficiency | Lower GWP than R-410A |

| R-134a | Used in some older systems or specialty applications | Moderate GWP, no ozone depletion |

| Natural Refrigerants (e.g., CO2, Propane) | Eco-friendly options with low impact | Very low GWP, safe for environment |

Why Refrigerant Choice Matters for Heat Pump Performance

The efficiency and environmental friendliness of heat pumps depend significantly on refrigerant characteristics. Selecting refrigerants with optimal thermodynamic properties ensures better heat transfer efficiency, reducing electricity usage and operational costs.

Additionally, regulatory bodies encourage the use of refrigerants with lower GWP to minimize environmental impact, pushing manufacturers toward greener alternatives that align with sustainability goals.

Safety and Maintenance Considerations Related to Refrigerant

Handling refrigerants requires professional care since leaks can reduce heat pump efficiency and pose environmental risks. Proper maintenance includes checking refrigerant levels, inspecting for leaks, and ensuring safe handling practices.

- Refrigerant leaks degrade system performance and increase operational costs.

- Some refrigerants are mildly toxic or flammable in concentrated amounts, so safety protocols are crucial.

- Regular servicing by certified technicians prolongs the lifespan of heat pumps and sustains efficient refrigerant use.

Future Trends: Eco-Friendly Refrigerants in Heat Pump Technology

The HVAC industry is rapidly evolving to adopt refrigerants with lower environmental impact. Some emerging refrigerants, such as hydrofluoroolefins (HFOs) and natural refrigerants like CO2 and propane, are gaining traction due to their negligible GWP and improved safety profiles.

These newer refrigerant options support global climate goals while maintaining or improving heat pump efficiency. Consumers can expect more heat pumps equipped with environmentally responsible refrigerants as regulations and technology advance.