Heat pumps and refrigeration cycles are foundational technologies in modern heating, ventilation, air conditioning (HVAC), and refrigeration systems. Both rely on similar thermodynamic principles but serve different purposes: heat pumps transfer heat from one environment to another to provide heating or cooling, while refrigeration cycles primarily remove heat to cool spaces or preserve food. Understanding their operation, components, and applications reveals how these technologies work efficiently to control temperature in residential, commercial, and industrial settings.

| Aspect | Heat Pump | Refrigeration Cycle |

|---|---|---|

| Primary Purpose | Transfer heat for heating and cooling spaces | Remove heat for cooling or freezing applications |

| Direction of Heat Flow | Can reverse (heating or cooling mode) | One-way (cooling mode only) |

| Common Applications | Home heating and cooling, water heating | Refrigerators, freezers, air conditioning, industrial cooling |

| Main Components | Compressor, evaporator, condenser, expansion valve | Compressor, evaporator, condenser, expansion valve |

| Energy Efficiency | Often more efficient for space heating than electric resistance heaters | Energy efficient for cooling but varies by system design |

Basic Principles of Heat Pumps and Refrigeration Cycles

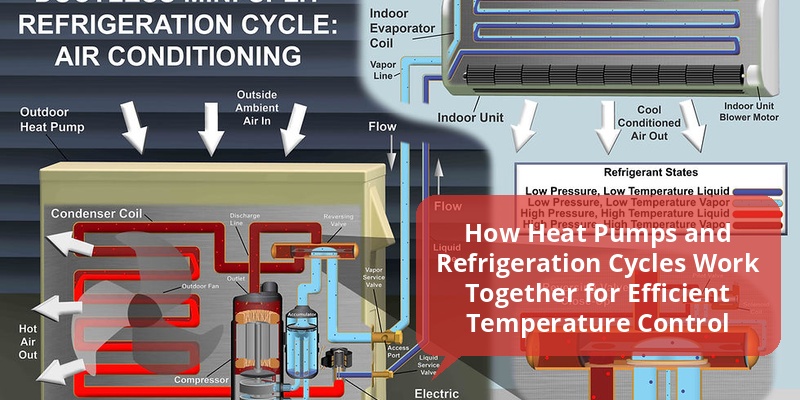

Both heat pumps and refrigeration cycles are based on the vapor-compression cycle, a thermodynamic process that moves heat by circulating a refrigerant through four key components: compressor, condenser, expansion valve, and evaporator. The refrigeration cycle absorbs heat from a low-temperature source and rejects it to a higher-temperature sink.

In the refrigeration cycle, heat flows in a single direction—from inside a cooled space (low temperature) to the outside environment (high temperature)—to maintain a lower temperature inside. In contrast, a heat pump system can reverse this flow, providing both heating and cooling by switching the roles of the evaporator and condenser depending on the desired mode.

Core Components and Their Functions

| Component | Function in Heat Pump | Function in Refrigeration Cycle |

|---|---|---|

| Compressor | Compresses refrigerant vapor to increase pressure and temperature | Same as heat pump |

| Condenser | Releases heat to the indoor environment during heating or to outdoors in cooling | Releases heat from refrigerant to surroundings |

| Expansion Valve | Reduces refrigerant pressure and temperature before entering evaporator | Same as heat pump |

| Evaporator | Absorbs heat from outside air or ground during heating mode | Absorbs heat from inside cooled space |

The compressor’s role in increasing the refrigerant’s pressure and temperature is critical for the effectiveness of both systems. Similarly, the expansion valve controls refrigerant flow, enabling efficient heat absorption and release.

How the Refrigeration Cycle Functions

The refrigeration cycle works by extracting heat from a low-temperature environment through the evaporator, where the refrigerant evaporates, absorbing latent heat. The resulting low-pressure vapor is then compressed by the compressor, raising its temperature and pressure. This hot, high-pressure vapor moves through the condenser, releasing heat to the surroundings, and condenses back into a liquid. The liquid refrigerant then passes through the expansion valve, dropping in pressure and temperature before re-entering the evaporator and repeating the cycle.

Heat Pump Operation and Reversibility

The heat pump operates similarly to a refrigeration cycle but includes a reversing valve that switches the direction of refrigerant flow. When in heating mode, the outdoor coil acts as an evaporator absorbing heat from the air or ground, while the indoor coil acts as a condenser, releasing heat to warm the interior. In cooling mode, the functions reverse with the indoor coil acting as the evaporator. This versatility makes heat pumps highly efficient for climate control, especially in moderate temperature ranges.

Energy Efficiency and Environmental Impact

Heat pumps typically deliver more than three units of heat energy for every unit of electrical energy consumed, thanks to their ability to transfer rather than generate heat. This coefficient of performance (COP) makes them significantly more energy-efficient than traditional electric resistance heaters.

Refrigeration systems have seen advances such as variable-speed compressors and improved refrigerants with lower global warming potential (GWP), contributing to better energy efficiency and reduced environmental impact. The emphasis on adopting refrigerants like R-1234yf and natural refrigerants (e.g., CO2, ammonia) is growing to meet environmental regulations.

Common Applications and Innovations

Heat Pumps

- Residential space heating and cooling

- Geothermal heat pumps using ground-source heat

- Hybrid systems pairing heat pumps with gas furnaces

- Heat pump water heaters that reduce energy cost for domestic hot water

Refrigeration Systems

- Commercial and residential refrigerators and freezers

- Air conditioning in buildings and vehicles

- Cryogenic and industrial cooling systems

- Cold storage for food and pharmaceuticals

Challenges and Limitations

Heat pumps can experience reduced efficiency in extremely cold climates due to limited heat available from the outdoor air, although cold-climate heat pump models mitigate this issue. Designing refrigeration cycles also requires balancing performance with refrigerant safety, environmental concerns, and regulatory compliance.

Proper system sizing, installation, and maintenance are essential to realize the full energy-saving potential and longevity of both heat pumps and refrigeration devices.

Future Trends and Developments

R&D continues to focus on enhancing heat pump performance at low temperatures, integrating smart controls for demand response, and developing refrigerants with minimal environmental footprint. Advances in materials and design are enabling more compact, quiet, and efficient units.

Refrigeration technology is evolving toward natural refrigerant use and digital monitoring systems to optimize operation and prevent leaks. These innovations promise to drive adoption of eco-friendly HVAC and refrigeration solutions in residential, commercial, and industrial sectors.