The heat pump refrigeration cycle is a fundamental technology used in heating, ventilation, air conditioning (HVAC), and refrigeration systems. It transfers heat from one location to another, providing both heating and cooling solutions efficiently. Understanding this cycle is essential for homeowners, HVAC professionals, and engineers aiming to optimize energy use and system performance.

| Component | Function | Heat Transfer Role |

|---|---|---|

| Evaporator | Absorbs heat from the environment | Heat absorption (cooling side) |

| Compressor | Compresses refrigerant vapor | Increases pressure and temperature |

| Condenser | Releases heat to the surroundings | Heat rejection (heating side) |

| Expansion Valve | Reduces refrigerant pressure | Prepares refrigerant for evaporation |

Fundamentals of The Heat Pump Refrigeration Cycle

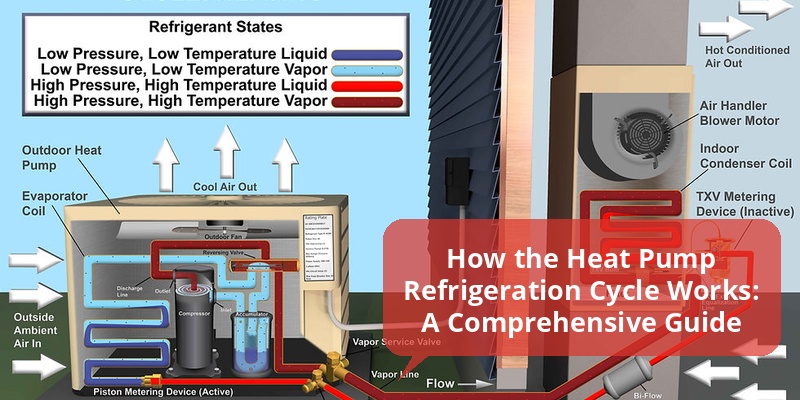

The heat pump refrigeration cycle works by circulating a refrigerant through various components that absorb and release heat. The process starts at the evaporator, where the refrigerant absorbs heat from the air or ground, causing it to evaporate into a vapor. This vapor then passes through the compressor, which increases its pressure and temperature significantly. Once compressed, the hot refrigerant vapor enters the condenser, where it releases heat to the target area (such as a home or building) and condenses back into a liquid. Finally, the liquid refrigerant passes through the expansion valve, dropping its pressure and temperature, before returning to the evaporator to repeat the cycle.

Key Components Of The Heat Pump Refrigeration Cycle

Evaporator

The evaporator is where the refrigeration cycle begins with heat absorption. It extracts heat from the external environment—air, water, or ground—even at low temperatures, making it effective in cold climates. The refrigerant evaporates by absorbing this heat, turning from a low-pressure liquid into a low-pressure vapor.

Compressor

The compressor plays a vital role by increasing the refrigerant’s pressure and temperature. This compression transforms the cold vapor into a high-pressure, high-temperature state, enabling heat release at the condenser. The compressor is often the most energy-consuming part of the system but critical for the heat pump’s efficiency.

Condenser

The condenser allows the hot refrigerant vapor to release heat to the indoor environment or hot water system. As it gives off heat, the refrigerant cools and condenses back into a high-pressure liquid. The condenser’s effectiveness determines how efficiently heat is transferred inside.

Expansion Valve

The expansion valve controls refrigerant flow into the evaporator, reducing its pressure abruptly. This sudden pressure drop cools the refrigerant sufficiently, preparing it for heat absorption again. Modern thermostatic or electronic expansion valves optimize performance by adjusting flow based on demand.

How The Heat Pump Refrigeration Cycle Provides Heating And Cooling

The heat pump refrigeration cycle can operate in two modes: heating and cooling. In heating mode, the system extracts heat from the outdoor air or ground and transfers it indoors via the condenser. Conversely, in cooling mode, the cycle reverses, extracting heat from inside a building and releasing it outside.

This reversible functionality is achieved by integrating a reversing valve, which changes the direction of the refrigerant flow. The ability to provide year-round climate control with a single system makes heat pumps popular for energy-efficient homes and commercial properties.

Advantages And Efficiency Of Heat Pump Refrigeration Systems

- Energy Efficiency: Heat pumps can deliver three to four times more heat energy than they consume in electrical energy, making them a cost-effective choice for heating and cooling.

- Environmental Benefits: By using electricity instead of direct combustion, heat pumps reduce greenhouse gas emissions when paired with clean energy sources.

- Low Operating Costs: Though the initial installation may be higher compared to traditional systems, operating costs are significantly lower over time due to superior efficiency.

- Versatility: Suitable for diverse climates and applications, including residential heating, commercial HVAC, and industrial refrigeration.

Common Refrigerants Used In Heat Pump Refrigeration Cycles

The choice of refrigerant affects the efficiency, environmental impact, and regulatory compliance of the heat pump system. Traditional refrigerants like R-22 are being phased out due to ozone depletion concerns, while newer options offer improved environmental profiles.

| Refrigerant | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Applications |

|---|---|---|---|

| R-410A | 2088 | 0 | Residential and commercial HVAC |

| R-134a | 1430 | 0 | Refrigeration and automotive air conditioning |

| R-32 | 675 | 0 | New generation HVAC systems with better efficiency |

| Propane (R-290) | 3 | 0 | Natural refrigerant used in small commercial refrigeration |

Factors Affecting The Performance Of Heat Pump Refrigeration Cycles

Several factors influence how effectively a heat pump refrigeration cycle operates. Ambient temperature is critical; as outdoor temperatures drop below freezing, the heat absorption capacity decreases, potentially requiring auxiliary heating systems.

Proper sizing and maintenance also affect cycle efficiency. Oversized units may cycle frequently, wasting energy, while undersized systems fail to meet demand. Routine checks on refrigerant levels, compressor condition, and coil cleanliness ensure consistent performance.

Insulation and Building Envelope

The efficiency of heat pumps improves significantly in buildings with good insulation and tight envelopes, reducing heat loss during winter and limiting heat gain in summer.

Modern Innovations Improving Heat Pump Refrigeration Cycles

Advances in technology have enhanced the heat pump refrigeration cycle’s efficiency and environmental friendliness. Variable-speed compressors adjust power use based on load requirements, reducing energy consumption and wear.

Smart thermostats and control systems optimize cycle timing, ensuring comfort while minimizing energy waste. Additionally, integration with renewable energy sources like solar panels further lowers operational carbon footprints.

Common Applications Of Heat Pump Refrigeration Cycles In The U.S.

- Residential Heating and Cooling: Widely used in homes for year-round temperature regulation, especially in moderate climates.

- Commercial HVAC Systems: Provide efficient climate control in offices, retail environments, and public buildings.

- Industrial Refrigeration: Used in cold storage and process cooling with enhanced energy savings.

- Water Heating: Heat pump water heaters efficiently supply hot water for residential and commercial use.