Heat pumps are widely used in residential and commercial HVAC systems due to their energy-efficient heating and cooling capabilities. One crucial operational process in heat pumps is pumping down in cooling mode. This technique helps protect the compressor and refrigerant system by managing refrigerant flow during shutdown or maintenance. Understanding how pumping down works can optimize system performance and extend the life of your heat pump.

| Term | Description |

|---|---|

| Pumping Down | Process of moving refrigerant to the condenser to protect the compressor during system shutdown. |

| Cooling Mode | Heat pump operation mode focused on removing heat from indoor air to provide cooling. |

| Compressor | Component that compresses refrigerant to enable heat transfer in the heat pump cycle. |

| Receiver Tank | Part of the system that temporarily stores refrigerant during pumping down. |

What Is Pumping Down in a Heat Pump?

Pumping down is a controlled procedure where the heat pump’s refrigerant is concentrated in the outdoor unit’s condenser and receiver tank during system shutdown or service. This process removes refrigerant from the evaporator and indoor piping, minimizing the risk of refrigerant leaks when the system is off or disconnected.

During pumping down, the compressor continues running while the expansion valve or metering device closes, preventing refrigerant from returning to the evaporator. This causes refrigerant to accumulate at the condenser side, protecting system components.

Why Pumping Down Is Important in Cooling Mode

Cooling mode pumping down plays a vital role in maintaining the heat pump’s integrity and performance. Its importance includes:

- Prevents Refrigerant Loss: By isolating refrigerant in the condenser, it reduces leak risks during maintenance or shutdown.

- Protects the Compressor: Ensures the compressor is not running with low refrigerant levels, which can cause overheating or damage.

- Simplifies Service Tasks: Technicians can safely work on indoor components without refrigerant escaping.

- Extends Equipment Life: Proper refrigerant management improves overall system durability and reliability.

How Pumping Down Works in Cooling Mode

The pumping down cycle in cooling mode initiates just before system shutdown. The primary steps include:

- Thermostat Signal: A signal from the thermostat commands the heat pump to stop cooling operations.

- Closing the Expansion Valve: The heat pump’s expansion valve closes, stopping refrigerant flow to the evaporator coil indoors.

- Compressor Operation: The compressor continues to run, pushing refrigerant from the evaporator to the condenser.

- Accumulation of Refrigerant: Refrigerant gathers in the outdoor receiver tank, depleting the evaporator coil.

- Compressor Shutdown: When a pressure switch detects the proper low pressure in the evaporator line, it signals the compressor to stop.

This controlled process ensures the refrigerant is safely stored in the outdoor unit, allowing technicians to perform repairs without refrigerant loss.

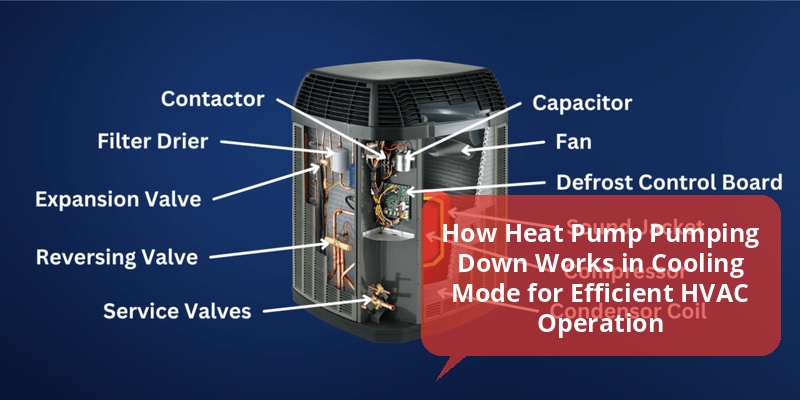

Common Components Involved in Pumping Down

| Component | Role in Pumping Down |

|---|---|

| Compressor | Continues running to move refrigerant out of the indoor coil during pumping down. |

| Expansion Valve or Solenoid Valve | Closes to isolate refrigerant inside the evaporator and indoor piping. |

| Receiver Tank | Stores refrigerant temporarily during pumping down. |

| Pressure Switch | Monitors system pressures to safely shut down the compressor once pumping down completes. |

Signs and Troubleshooting of Pumping Down Issues

If pumping down does not occur properly, it can lead to refrigerant leaks, compressor damage, or system inefficiencies. Common signs of pumping down issues include:

- Heat pump continuously running without proper shutdown.

- Refrigerant leaks around indoor piping or evaporator coils.

- Pressure switch fails to signal the compressor to stop.

- Unusual noises or vibrations during shutdown.

Troubleshooting steps to resolve pumping down problems involve:

- Inspecting solenoid or expansion valves for mechanical failures or blockages.

- Testing pressure switches to ensure accurate operation.

- Checking refrigerant charge and line integrity for leaks.

- Verifying the thermostat and control wiring for correct signals.

Optimizing Heat Pump Performance by Proper Pumping Down

Integrating pumping down best practices can enhance heat pump longevity and operational efficiency:

- Routine Maintenance: Schedule regular inspections focused on valves, pressure switches, and refrigerant charge.

- Leak Detection: Use electronic leak detectors during service tasks to identify escaping refrigerant early.

- System Upgrades: Modern heat pumps may include advanced control boards that automate pumping down, improving reliability.

- Professional Service: Employ qualified HVAC technicians to manage pumping down procedures and repairs safely.

How Pumping Down Differs in Cooling and Heating Modes

While pumping down is commonly associated with cooling mode, understanding its behavior in heating mode is useful:

| Aspect | Cooling Mode Pumping Down | Heating Mode Pumping Down |

|---|---|---|

| Refrigerant Location | Refrigerant is pumped into the condenser and receiver tank outdoors. | Refrigerant is pumped into the condenser, which acts as an indoor coil in heat mode. |

| Valve Operation | Expansion valve closes to isolate indoor evaporator. | Reversing valve changes position but pumping down operates similarly on indoor coil isolation. |

| Purpose | Prevents refrigerant loss and protects compressor during cooling mode shutdown. | Ensures refrigerant containment during heating mode shutdown or service. |

Understanding these operational differences helps HVAC professionals tailor maintenance and troubleshooting effectively.