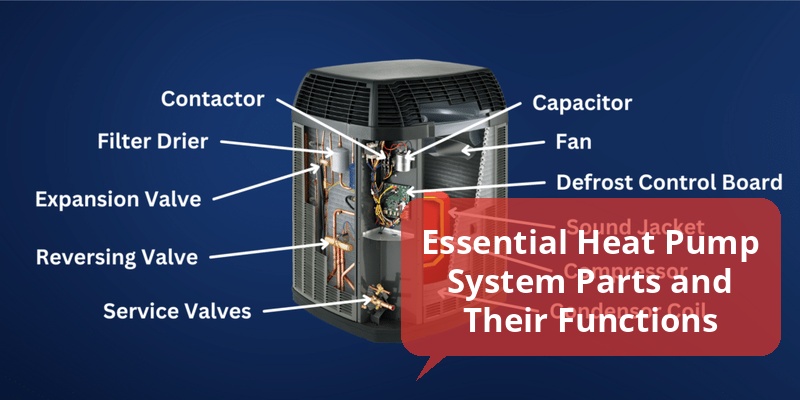

Heat pump systems are an energy-efficient way to heat and cool homes and commercial buildings, utilizing components that work together to transfer heat rather than generating it from scratch. Understanding the essential heat pump system parts is crucial for homeowners and technicians to optimize performance, maintain longevity, and troubleshoot issues effectively. This article explores the key components of heat pump systems, how they operate, and their roles in efficient temperature control.

| Heat Pump Component | Primary Function | Location |

|---|---|---|

| Compressor | Compresses refrigerant to raise pressure and temperature | Outside Unit |

| Condenser Coil | Releases heat from refrigerant to the outside air (heating mode) | Outside Unit |

| Evaporator Coil | Absorbs heat from outside air into the refrigerant (cooling mode) | Inside Unit |

| Expansion Valve | Regulates refrigerant flow and reduces pressure | Near Evaporator Coil |

| Reversing Valve | Switches refrigerant flow to alternate between heating and cooling | Near Compressor |

| Air Handler | Distributes conditioned air throughout the building | Inside Unit |

| Thermostat | Controls the heat pump operation based on desired temperature | Indoor Location |

Compressor: The Heart of the Heat Pump System

The compressor is a critical component situated in the outdoor unit, often referred to as the heart of the heat pump system. It compresses the refrigerant gas, raising its temperature and pressure so it can release or absorb heat efficiently. This process enables the transition of heat between indoor and outdoor environments. A malfunctioning compressor can significantly reduce system efficiency or lead to complete failure, making regular inspection and maintenance essential.

Condenser Coil and Evaporator Coil: Heat Transfer Champions

Heat pumps rely on two coils to transfer heat rather than generate it. The condenser coil, usually located in the outdoor unit during heating mode, releases heat absorbed by the refrigerant into the surrounding air. Conversely, the evaporator coil, positioned in the indoor unit, absorbs heat from outside air during the cooling cycle. These coils are vital for efficient heat exchange and directly influence the system’s performance.

Expansion Valve: Regulating Refrigerant Flow

The expansion valve plays a crucial role by controlling the flow of refrigerant into the evaporator coil. It reduces the refrigerant’s pressure, allowing it to expand and cool before absorbing heat from the environment. Precise function of the expansion valve is necessary to maintain optimal system efficiency and prevent issues like freezing or overheating.

Reversing Valve: Switching Between Heating and Cooling

A defining feature of heat pumps is their ability to provide both heating and cooling. This versatility is possible due to the reversing valve, which reverses the flow of refrigerant depending on whether the system is in heating or cooling mode. This valve is pivotal in seasonal temperature control and allows the unit to efficiently switch functions without manual intervention.

Air Handler and Blower: Circulating Conditioned Air

The air handler, located inside the building, contains the blower which moves warm or cool air through the ductwork into living spaces. It houses the evaporator coil and filter as well, ensuring air quality and system efficiency. Proper sizing and maintenance of the air handler are essential for effective climate control and comfort.

Thermostat: The Control Interface

The thermostat serves as the user interface for the heat pump system, allowing occupants to set desired indoor temperatures. Modern thermostats can optimize heat pump operation with programmable settings and smart features, adjusting performance for energy savings and comfort. Proper thermostat placement and calibration are critical for accurate temperature control and efficient system usage.

Additional Components Supporting Heat Pump Performance

- Defrost Control: Prevents the outdoor coil from freezing by initiating defrost cycles when needed.

- Filters: Maintain clean airflow to improve indoor air quality and protect system components.

- Auxiliary Heat: Provides supplemental heat during extremely cold conditions when the heat pump alone cannot meet demands.

- Drain Pan and Condensate Line: Remove moisture collected from the evaporator coil to prevent water damage.

Common Issues Related to Heat Pump Parts

Wear and tear or malfunction of key heat pump components can dramatically reduce system efficiency. Common problems include compressor failure, refrigerant leaks, blocked coils, malfunctioning reversing valves, and thermostat errors. Understanding the function of each part helps in diagnosing issues quickly and scheduling preventative maintenance to avoid costly repairs.

Maintenance Tips to Prolong Heat Pump Life

- Regularly clean or replace air filters to maintain airflow.

- Inspect coils annually and clean as needed to ensure efficient heat exchange.

- Check refrigerant levels and refill if low to optimize performance.

- Test the reversing valve and expansion valve functionality seasonally.

- Schedule professional inspections to monitor compressor health and electrical components.

Choosing Quality Parts for Replacement and Upgrade

When repairing or upgrading heat pump systems, selecting high-quality parts from reputable manufacturers can improve efficiency and system longevity. Components should meet industry standards such as those set by AHRI and ENERGY STAR to ensure compatibility and optimal performance. Consult HVAC professionals to choose the right parts tailored for specific system models and home requirements.

Heat Pump Parts and Energy Efficiency Standards

Heat pump components directly impact energy efficiency ratings like SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Seasonal Performance Factor). Modern systems use advanced compressors, variable-speed blowers, and smart thermostats to comply with energy regulations and reduce utility costs. Upgrading outdated parts to newer, more efficient versions can substantially enhance a system’s eco-friendliness and reduce operational expenses.