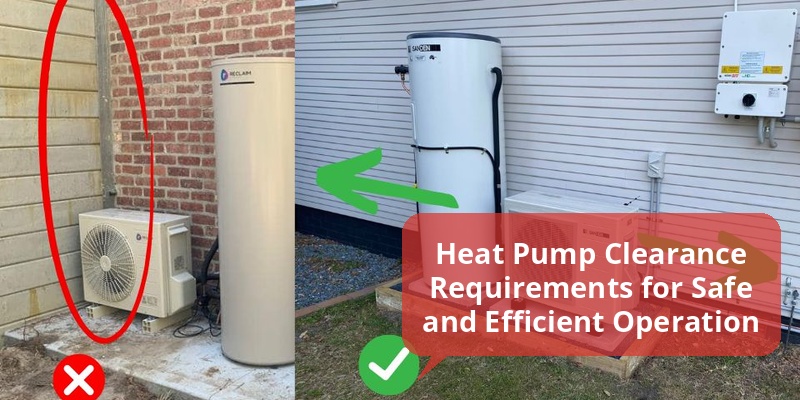

Heat pump clearance requirements are essential for ensuring efficient operation, safety, and longevity of the unit. Proper clearance allows for adequate airflow, maintenance access, and prevents potential hazards. This article outlines the key clearance guidelines homeowners and contractors should follow when installing and servicing heat pumps.

| Component | Minimum Clearance | Purpose |

|---|---|---|

| Sides of Unit | 12 to 24 inches | Allows proper airflow and heat exchange |

| Rear of Unit | 12 to 24 inches | Prevents obstruction to condenser coil |

| Top of Unit | 60 inches (5 feet) | Ensures exhaust air dissipates freely |

| Power Disconnect | Within sight and 3 feet from unit | Easy access for maintenance and safety |

| Nearby Structures | 3 feet or more | Prevents blockage and fire risk |

Importance Of Proper Heat Pump Clearance

Maintaining adequate clearance around a heat pump is critical. Restricted airflow reduces efficiency and can cause the system to overheat, leading to increased energy consumption and component failure. Clearance also facilitates routine maintenance, repairs, and inspections. Furthermore, proper spacing minimizes fire hazards by keeping the unit away from flammable materials or structures.

Recommended Clearance Distances For Heat Pumps

Clearance guidelines vary slightly depending on manufacturer specifications and local codes, but general recommendations for typical residential heat pumps include:

Sides And Rear Clearance

A minimum of 12 to 24 inches clearance on all sides and the rear of the unit is standard to ensure unobstructed airflow through the condenser coils. Narrow spaces can trap heat and dirt, adversely affecting performance.

Top Clearance

The top of the heat pump needs at least 60 inches (5 feet) of clearance to allow hot air exhausted upwards to disperse safely without recirculating into the system.

Clearance From Walls And Structures

Unit proximity to walls, fences, or overhangs should be no less than 3 feet to prevent airflow restrictions and reduce the buildup of debris around the heat pump. This also minimizes potential noise disturbance to occupants.

Access For Service And Maintenance

A clear working space of at least

Clearance Requirements For Heat Pump Installation Sites

Selecting an appropriate installation site is equally important. Some considerations include:

- Positioning away from high traffic areas to avoid accidental damage.

- Ensuring drainage so water does not accumulate under the unit.

- Placement on a level, stable surface to maintain unit integrity.

- Avoiding locations near combustible materials to reduce fire risk.

Common Local And Manufacturer Regulations

Building codes and HVAC manufacturer manuals provide specific clearance requirements based on unit model and climate zone. It is essential to consult these documents prior to installation because they may mandate unique clearances or additional safety features.

Many jurisdictions require the disconnect switch to be located within sight and no more than 3 feet from the heat pump for quick power shutoff during emergencies.

Effects Of Inadequate Clearance On Heat Pump Performance

Improper clearances can lead to several operational issues, including:

- Reduced efficiency: Poor airflow forces the heat pump to work harder, increasing energy costs.

- Increased wear and tear: Overheating causes premature compressor and component failure.

- Higher repair costs: Restricted access complicates maintenance and diagnostic efforts.

- Safety hazards: Risk of fire and electrocution from blocked vents or servicing difficulties.

Tips For Maintaining Proper Heat Pump Clearance

Homeowners and service providers can maintain proper heat pump clearance by:

- Regularly cleaning around the unit to remove debris, leaves, and snow.

- Trimming vegetation to prevent encroachment.

- Checking clearance distances periodically to ensure they remain compliant with regulations.

- Installing barriers or protective covers that do not impinge on airflow but keep out animals and dirt.